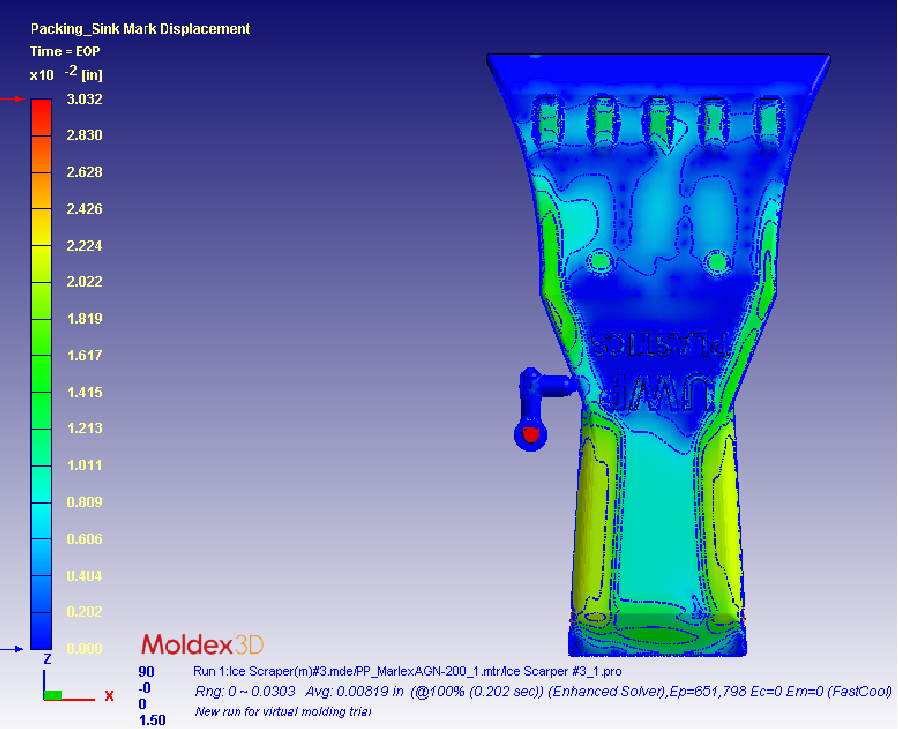

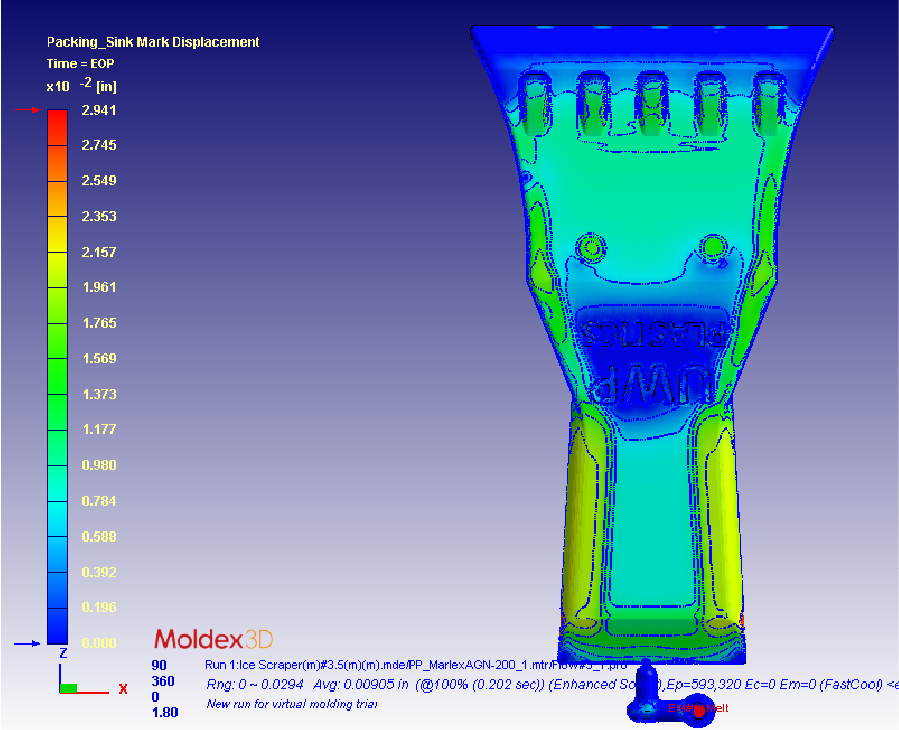

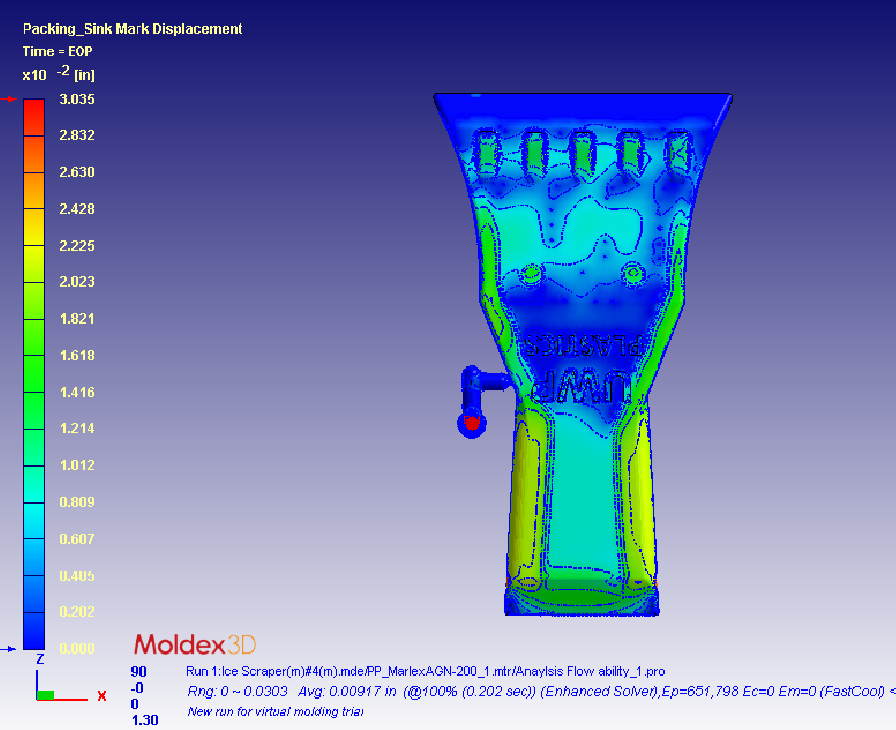

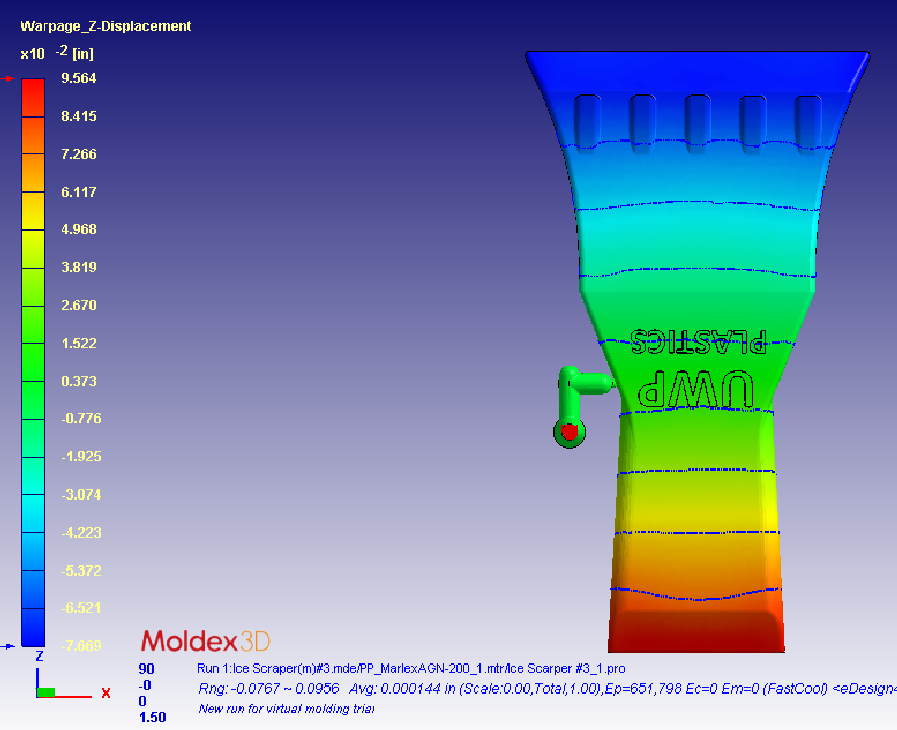

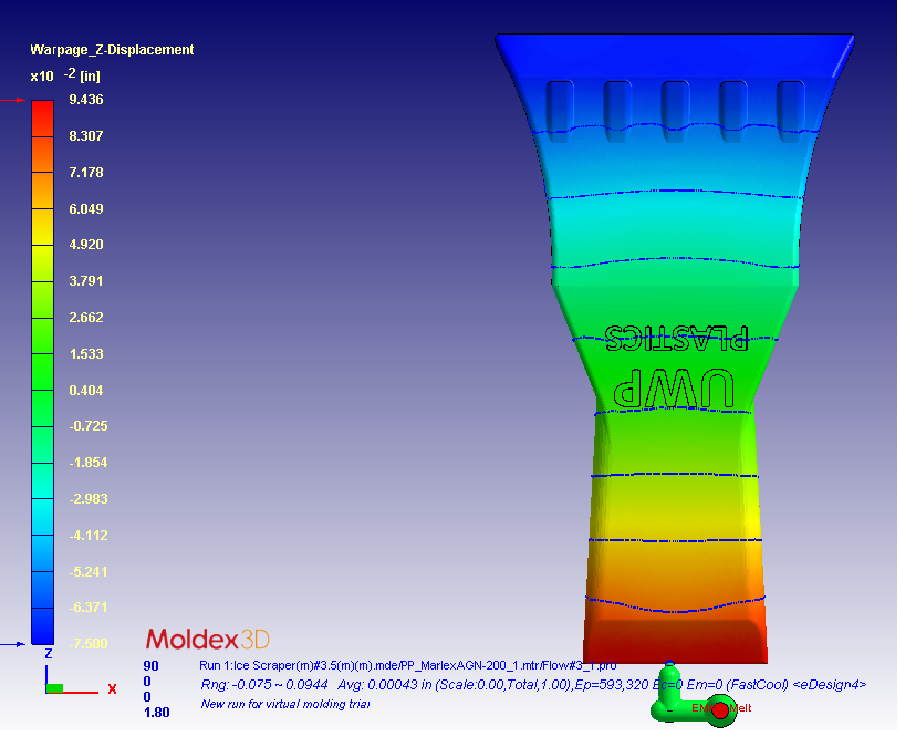

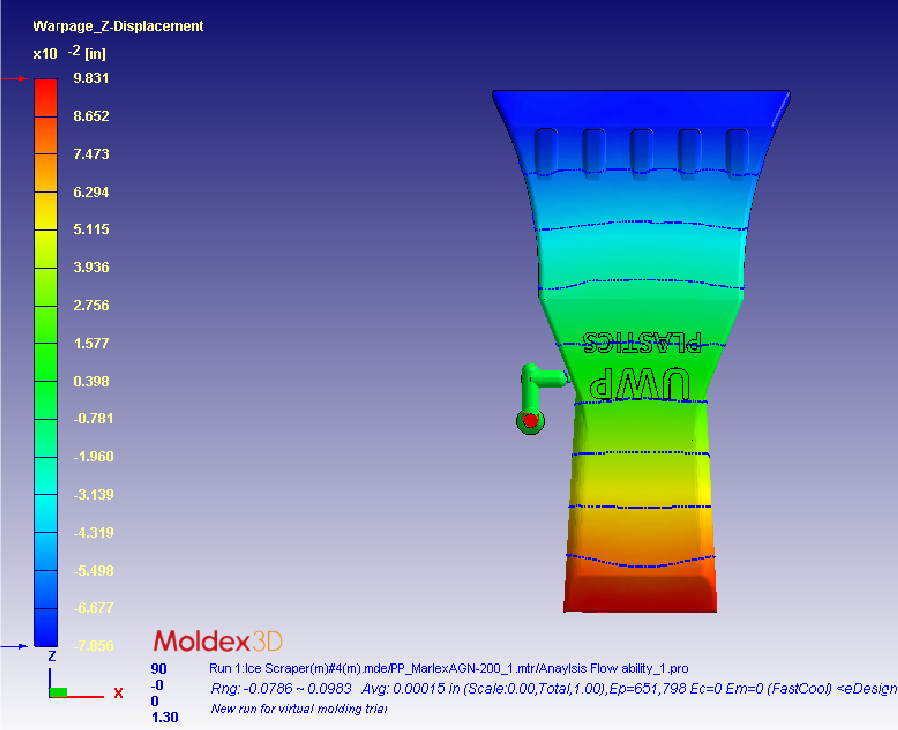

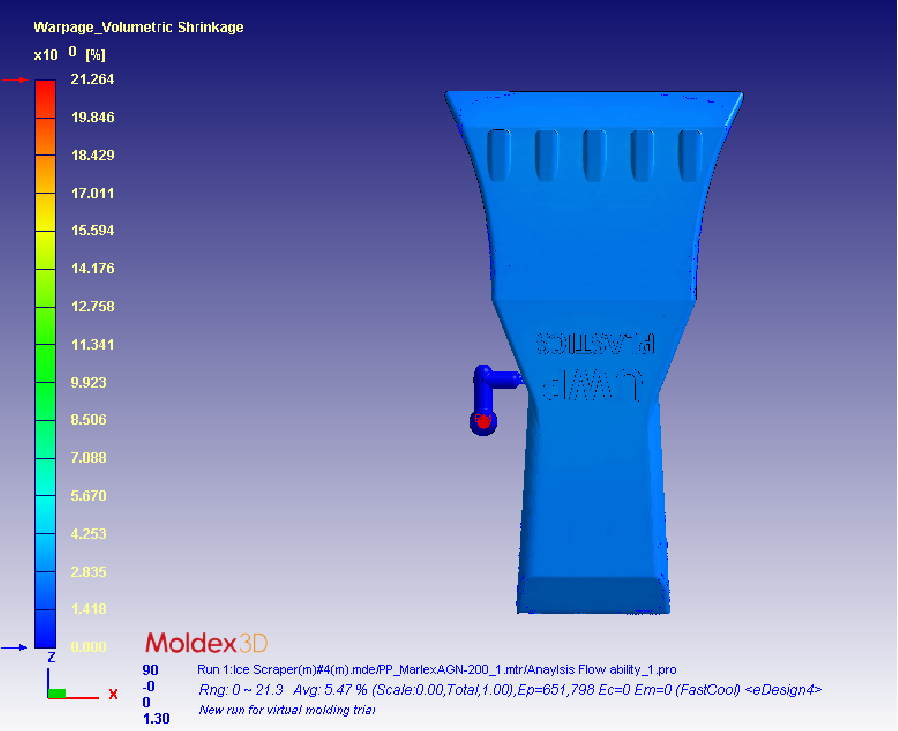

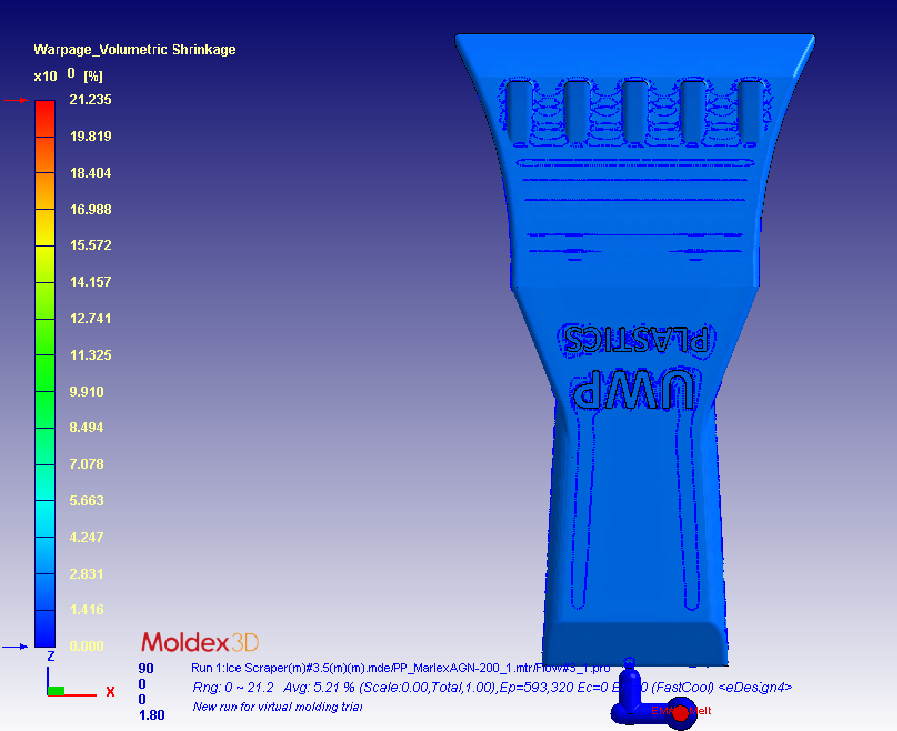

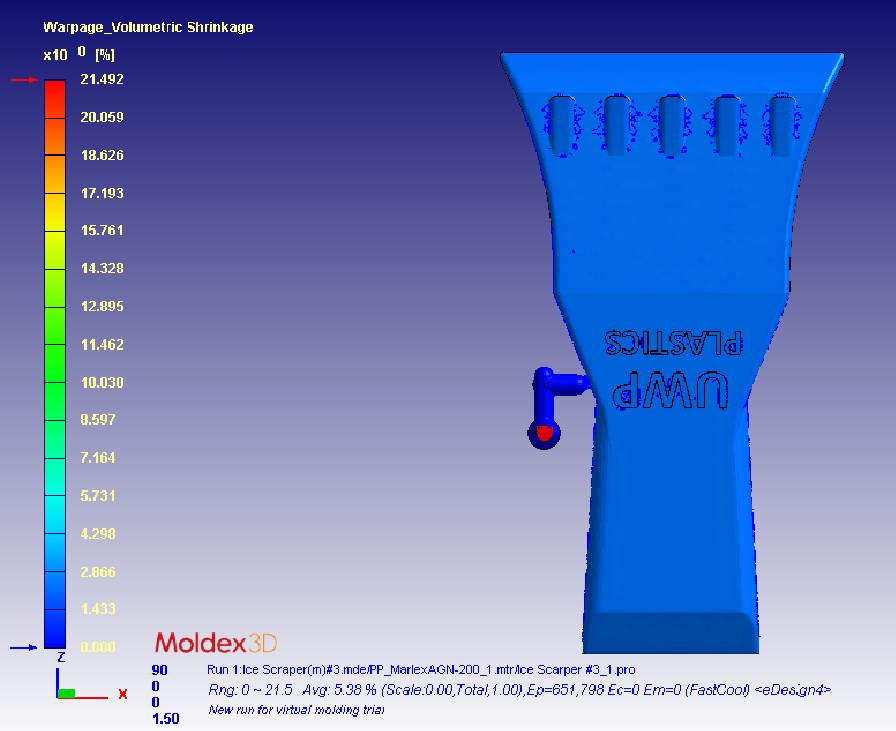

The students at the University of Wisconsin Platteville utilized Moldex3D eDesign to run simulations on an ice scraper to investigate the fluid dynamic flow. First, they simulated the original design of the ice scraper. Second, they changed the gate point location and simulated the process again. Last, they adjusted the distance between the cooling channel and the part and simulated this design change. Through this process, the students were able to compare the different analysis results of the above three design changes and have a better understanding on plastics flow behaviors during the injection molding. Thus, they can further apply Moldex3D CAE technology in real production to predict possible defects before manufacturing. Using Moldex3D eDesign to simulate the three kinds of part designs to look into the flow behaviors as well as sink marks and warpage results. During school classes, the students at University of Wisconsin Platteville gain knowledge of plastic injection molding, but they are not able to visualize plastic flow behavior and observe the production results with different design or parameters. Through Moldex3D’s simulation technology, they will be able to look into the plastic flow and decide the optimized product design. In this case, the students would like to use the model of an ice scraper as an example in simulation software to help get a better understanding of the problems people run into when designing the mold for production. The function of the ice scraper designed by University of Wisconsin Platteville students is to scrape ice off the window (Fig. 1). The main analysis they were running was to compare the differences of gating and cooling channel distances that could affect the flow dynamic. The following design changes were simulated in the case study:    1. Original design After running the analysis projects, the students first compared the sink mark displacement. As shown in Fig.2; there were not big differences among the sink mark results of different design changes. Neither did they display apparent surface defects. Second, the students compared the Z-displacement results (Fig. 3) and the shrinkage analysis results (Fig. 4). As shown in Fig. 3, Gating #2 appeared to have relatively less displacement, which is from -0.07500 to 0.09436 inch. However the overall displacement and shrinkage results of 3 design changes still did not show great diversities. Apart from changing the part design according to Moldex3D simulation results, the students also observed the plastics flow ability on Moldex3D software. The flow ability of the resin is an important parameter in the injection process. The flow of the resin could be affected by gating, wall thickness, and the part design itself. To have a better understanding on the flow ability will help designers to decide where to locate the gates, what type of sprue to use, and how thick the wall should be. The velocity of the molecular flow has orientation. The speed of plastic flow in the center is higher compared to the plastic flow near the wall. The reason is that plastics near the wall will be experiencing speed reduction due to the friction from the wall. While the plastics flow, the rubbing molecules against each other will cause frictional heating. A high aspect ratio of the giant polymer molecules and non-uniformity of the flow velocity in the cross section of flow leaders will cause shear. Through Moldex3D’s simulation technology, users would have a better understanding on the flow ability and how to further improve the part design and quality. The use of Moldex3D plastic injection molding simulation software helps students apply the injection molding knowledge acquired in the classes to real-world design challenges. As a result, the students were able to understand how parts are filled and how gate locations affect part quality during the injection molding process. The software helps students not only advance their skills and knowledge of injection molding, but also helps them further gain a competitive edge by working with the same technology used by industry personnel, helping students get ready for the job market. In the industry application, they can further utilize Moldex3D to predict and prevent potential defects and possible errors at the early stage before manufacturing. Pure White Bopp Thermal Lamination Film Pure White Bopp Thermal Lamination Film,Bright White Bopp Laminating Roll,Snow White Bopp Laminate Film,Pure White Bopp Film JIANGYIN HONGJU NEW MATERIALS CO.,LTD , https://www.hongjuspecialfilm.com

Executive Summary

Objectives

Case Study

Fig. 1 Â Product design: An ice scraper

Fig. 1 Â Product design: An ice scraper

2. Changing gate point location (Gating #2)

3. Adjusting the distance between the cooling channel and the part from 1/2 inch to 1/4 inch

Original

Gating #2

¼ inch cooling channel distance

Fig. 2 Â Sink mark displacement results of 3 design changes

Original

Gating #2

¼ inch cooling channel distance

(Z-Displacement: -0.07669 ~ 0.09564 inch)

(Z-Displacement: -0.07500 ~ 0.09436 inch)

(Z-Displacement: -0.07856 ~ 0.09831 inch)

Fig. 3 Â Z-displacement results of 3 design changes

Original

Gating #2

¼ inch cooling channel distance

Fig. 4 Â Shrinkage results of 3 design changes

Results

University of Wisconsin Applies Moldex3D in Academic Research to Predict Plastic Product Defects

Customer Profile